22 June 2006

Component Storage Ideas

| P/N | Dia. | Height | Price

|

| 4332T31 | 1-1/2" | 1/2" | $6.92(12)

|

| 4332T21 | 2-3/8" | 3/4" | $6.96(12)

|

| 4332T23 | 4" | 1-1/8" | $7.85(6)

|

For parts storage I built some trays that hold tin-plated steel cans

available from

McMaster Carr.

I chose shallow storage cans so that

parts could be easily removed from the containers with tweezers. I

chose a tray size of 12-3/8" x 12-3/4" which allows a reasonable

amount of cans and does not take up too much space on the workbench.

The 1-1/2" diameter can is good for resistors and capacitors, the

2-3/8" can for ICs and semiconductors and the 4"

can for inductors, connectors and crytals.

Tray Construction

The main part of the tray, the plywood assembly, is built by fastening

a plywood square with through-holes to the top of a plywood square

without holes. Oak trim is attached to three sides of the plywood

assembly and an oak front to the fourth.

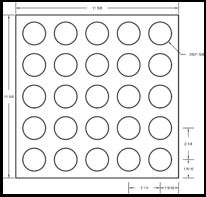

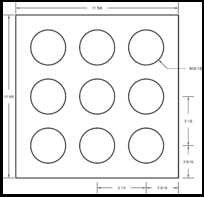

The tray for the 1-1/2" diameter tins holds 25. The tray for the

2-3/8" diameter cans holds 9. The tray is constructed out of two

pieces of plywood and some oak trim. I used scrap plywood

(Baltic~Birch) for the base. The trim is leftover sapwood from the oak

tree that was in my backyard.

Building Trays for 1 1/2" diameter cans

- From sheets of 1/2" and 1/4" plywood rip an equal number of 11-5/8" squares.

- Tape the 1/4" squares together in a stack so that all of the

squares can be drilled at the same time.

- Drill the holes as specified in the fabrication drawing.

- Glue and brad nail each 1/4" square to a 1/2" square.

- Sand the edges of the plywood assembly to 120grit and remove the dust.

- Glue oak trim to three of the edges of the plywood assembly. I

used 3/4" wide by 3/8" thick strips of oak.

- Glue an oak front to the uncovered edge of the plywood assembly.

I used a 1" wide by 3/4" thick strip of oak.

- Sand the assembly, remove the dust and seal with Polyurethane.

|

|

| Finished Tray

| Fabrication Drawing

|

Building Trays for 2 3/8" diameter cans

- From sheets of 1/2" and 1/4" plywood rip an equal number of 11-5/8" squares.

- Tape the 1/2" squares together in a stack so that all of the

squares can be drilled at the same time.

- Drill the holes as specified in the fabrication drawing.

- Glue and brad nail each 1/2" square to a 1/4" square.

- Sand the edges of the plywood assembly to 120grit and remove the dust.

- Glue oak trim to three of the edges of the plywood assembly. I

used 3/4" wide by 3/8" thick strips of oak.

- Glue an oak front to the uncovered edge of the plywood assembly.

I used a 1" wide by 3/4" thick strip of oak.

- Sand the assembly, remove the dust and seal with Polyurethane.

|

|

| Finished Tray

| Fabrication Drawing

|

Watchmaker's Cases

Watchmaker's cases are available from

Lee Valley

.

The cases are glass-topped aluminum cans. I use the larger

sizes for storage of inductors, crystals and connectors. I found the

33mm diameter lid to be difficult to remove but the 53mm diameter

worked fine.

Specifications and pricing are available

here

Toolbox Trays

Also available from

Lee Valley

. are

these stamped steel trays that are designed to slide into a slot made

from the kerf of a standard tablesaw blade. The trays come in heights

of 1", 2" and 3" with prices between $7-$9.

Specifications and pricing are available

here